Nikelio lydiniu dengti reaktoriai

Nickel-6 reaktorius yra atsparus redukuojančioms, oksiduojančioms ir neutralioms sąlygoms bei pasižymi išskirtiniu atsparumu šarminiams šarmams esant aukštai temperatūrai. Nikelio lydiniu dengti reaktoriai | Nikelio lydinio reaktoriai/ Nikelio lydinio reaktoriai/ Nikelio reaktoriai/ Nikelio lydinio dengimo reaktoriai/ Nikelio lydinio slėginiai indai/ Nikelio lydinio slėginiai reaktoriai

- HXCHEM

- Kinija

- 80 dienų po apmokėjimo

- 5 rinkiniai per mėnesį

Detalės

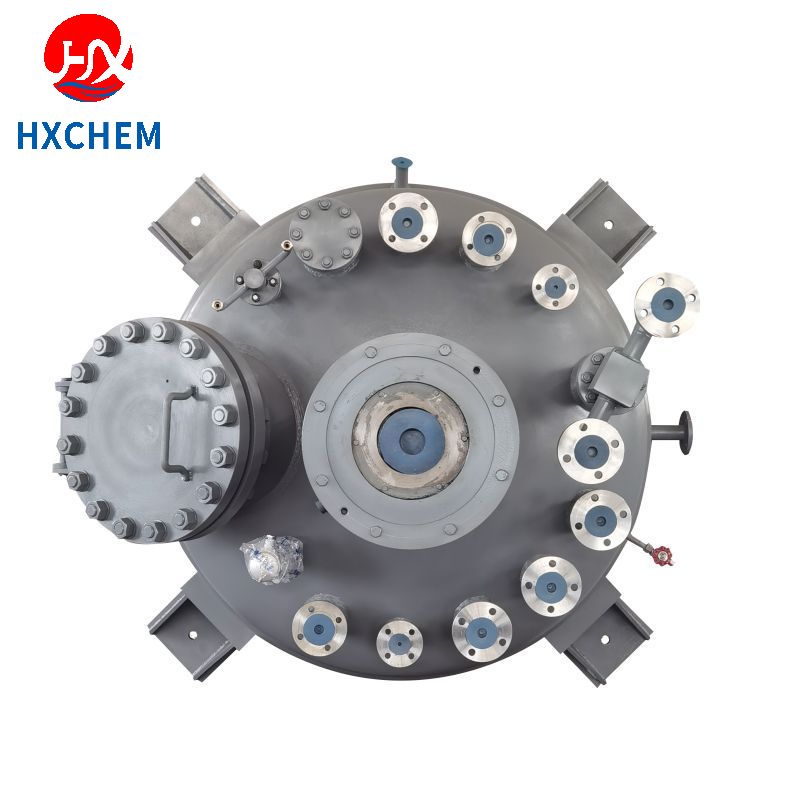

Nickel alloy pressure reactors

Introduction

Nickel-6 (

Application: H acid;Alkali melting process;

Nickel-based alloy reactor | Nickel pressure reactor

Product Features

? Large scale production- maximum volume reach to 100m3

? Max pressure: 200 bar; Max temperature up to 300 ℃

? Material: Nickel-6(Ni6)

? When cladding plates be considered, including base material for strength and clad material for anti-corrosion. Reduce costs for you!

? Low to high torque magnetic couplings: static seal with no leakage.

? Accurate Impeller selected for the mixing mission and requires.

? Internal cooling coil, vent port, liquid/powder charging, dip tube, thermowell, safety rupture disc, pressure safety valve, flush bottom outlet, baffles, light & sight glass, handhole/manhole, etc.

Nozzles, manual / automated valves, fittings, control panel & accessories offered based on requirement.

? Lugs or floor stand leg support.

Technical Specifications

| Model | FCH 1000~100000 |

| Norminal volume | 1000L-100m3 |

| Material | Nickel |

| Working pressure | -1~200 bar |

| Working temp. | 0~300℃ |

| Motor power | 5.5kW-125kW |

| Stirring speed | 200~400rpm |

| Sealing method | Magnetic seal Mechanical seal |

| Stirrer | Porpeller;Paddle type; Anchor type;Turbine type Other as designed |

| Head type | Elliptical type Conical type Hemispherical type Flat type |

| Heating type | Oil electric heating Oil heating Steam heating |